QUALITY

Home / Quality

ASSURED QUALITY

Idukki Ready-mix has a well-experienced team in manufacturing concrete mixes. All our types of equipment and delivery trucks are properly handled by experts. Even in delivery time, it’s happening under expert supervision.

Fully documented quality control processes and procedures form an integral part of our Quality Management System at Idukki Readymix. We are proud of our reputation for having what are, arguably, the most stringent testing programs conducted in our industries

INSTRUCTIONS

- Early & proper curing has to be done at site.

- Do proper shuttering & supports.

- Do proper checking of thickness at the time of concrete.

- Do proper retrowel of concrete.

- Don't add water or any chemicals at site without the consent of our QC technicians.

- Don't over vibrate, it may cause the possibility of cracking.

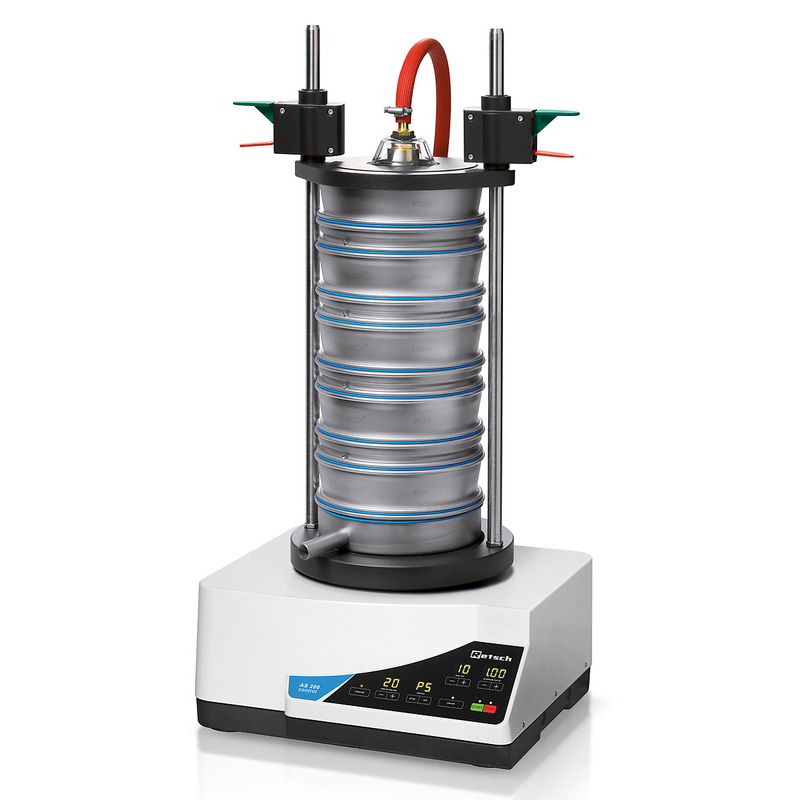

Various Tests Conducted In Our QC Lab

Flakiness and Elongation Test

The Flakiness Index is the percentage by weight of particles in it, whose least dimension (i.e. thickness) is less than three-fifths of its mean dimension. The Elongation Index is the percentage by weight of particles in it, whose largest dimension (i.e. length) is greater than one and four-fifths times its mean dimension.

A comparison with conventional site mix

- Save money by saving time.

- Minimum number of laborers.

- Uniform mix from a fully computerized batching plant.

- Proper quality checking by professional QC technicians.

- Material stocking space is not required on sites.

- Made on demand before being delivered.

- 24/7 delivery – same and next-day delivery.

- Consumption of time is very high compared to ready-mix concrete.

- Number of labors is more.

- There won’t be uniformity of mix by batch by batch, also, we can’t control the water-cement ratio.

- No proper quality checking of raw materials.

- Much more space is required for the stocking of raw materials.

At Idukki Ready-mix Concrete (IRMC), concrete is produced in its fully automated and computerized concrete batching plants. We manufacture and supply concrete mixes that are specified by the customer, the customer specification is designed by producing trial mixes by the technically sound quality team in its well-equipped laboratories as per established procedures to comply with various provisions of Indian standards.

IRMC’s experienced logistics team works closely with the plant and the clients to ensure that the concrete of specified quality is delivered on time and in the appropriate quantities.

IRMC Provides a Uniform Mix From a Fully Computerized Batching Plant Ensures the highest compressive strength with fast construction without any compromise in Results and also Timely Delivery of Our Concrete.

Transport :

Once a customer places an order on Idukki Ready-mix, the survey team will survey the site to ensure that the transit mixer trucks can access the site.

Factors the survey team considers are:

- The site approach road and the ground condition up to the delivering point for the transit mixer should be safe

- Sufficient space should be available for the transit mixer to access the delivery point

- The clearances should be sufficient for moving the equipment.

Pumping Concrete :

Pumping is one of the most efficient means of pouring concrete.

- Hands on team with highly professional experience in the ready- mix concrete.

- Strong relationships with key vendors, ensuring consistent and uninterrupted supplies.

- Robust Quality Control processes that ensures each batch of concrete adheres to consistent quality standards.

As a part of our end-to-end building solutions, we offer our customers unparalleled time and cost savings by leveraging the reach of our national supply chain and amassing material demand across multiple projects to lower pricing.We decode our client’s complete requirements and ensure timely delivery of the quantity and mix, ensuring reduction in unnecessary inventory carrying costs and no delay due to non-availability.

Better prices shouldn’t sacrifice quality. We hold every product to the highest design, durability and environmental standards. Our unique approach to the construction of buildings and integrated national supply chain offers newfound quality, scale, and efficiency to residential and commercial building projects. We adhere to strict quality norms, and all our suppliers are pre-vetted and are subjected to recurrent quality audits.